Description

Introduction:

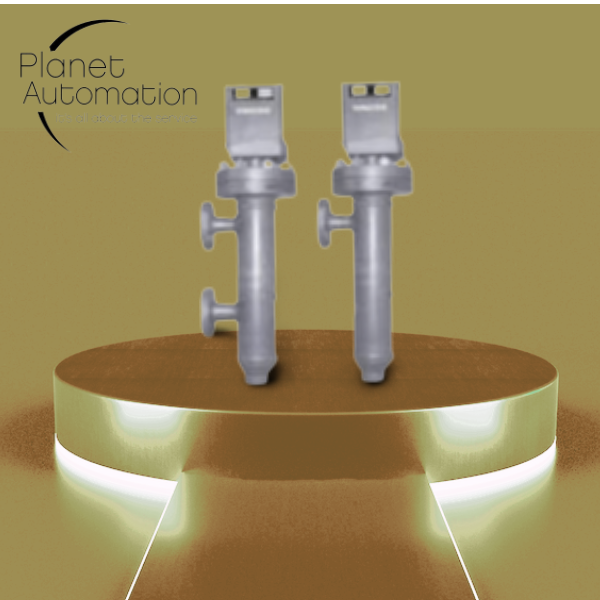

Industrial Water Level Controls are Magnetically operated Controls, Vertical Type in Float Chambers, meant for external Mounting on Steam Boilers/Vessels/Tanks and are designed to meet such requirements of Controls as Automatic on/off Control of Feed Pump, High and / Low Level Alarm, Burner cut out or any combination of these. These are mounted with independent Steam and Water connections with isolating valves and normally mounted vertically close to the Boiler Gauge Glasses.

Operation:

A permanent Magnet of the Float Rod Slides vertically inside a non- magnetic centre Tube and transfers the movement of the Float to

secondary Magnet in each Switch Unit. Self holding Switch Units, located on vertical support Rods in proximity to the Centre Tube and

positioned by Clamp Screws, have 2 pairs of contacts operated with a snap action and held by repulsion between the secondary and Tertiary Magnets ofthe Switch Unit Assembly.

Adjustments:

The Switch Head incorporates two/three/Four sets of Switch Units and “Differential” in operation between the sets are adjustable.

Version :

i)Side and Bottom Version with ends to 1″ NB, BS 10, Table ‘H’ suitable for a maximum operating Pressure of 25C psig (17.5 kg/cm2) of Steam.

ii)Side and Side Version with ends to 1″ NB, BS to Table ‘H’ suitable for a maximum operating Pressure of 250 psig (17.5 kg/cm2) of Steam, with Centre to Centre distance of Flanges at 216mm / 340 mm /400 mm /450 mm etc suiting customers requirements.

iii)Side and Side Version with ends to 1″ NB, BS 10 Table ‘J’ /ANSI B 16.5, -150, 300 and 600 LBS Ratings, suitable for related operating pressures of steam, with Centre to Centre distance of Flanges at 216mm / 340 mm / 4oC mm / 450 mm etc. suiting customers requirements.

Reviews

There are no reviews yet.